Energy efficiency, reduction of fossil fuel usage, and improvement of recyclability of your packaging: solutions exist to transform your industry and achieve your net-zero objectives.

Across the globe, Veolia specialists with a double expertise in the Food and Beverage industry and GHG (Greenhouse Gas) emissions reductions are here to assist you to decarbonize your industry.

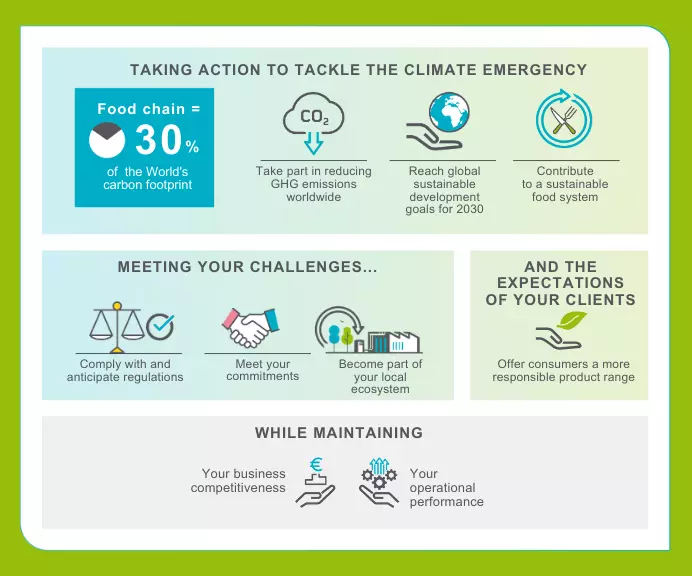

The urgency to act

In a context where the climate emergency is becoming increasingly pressing, it is urgent to take action to maintain the food system and meet the needs of a growing population.

Decarbonizing your industry and value chain is not only a positive contribution to global challenges but also one for your own benefits (risk reduction), aligning with your customers' environmental aspirations.

With our decarbonization solutions, you will ensure compliance with evolving regulations, you will uphold your commitments by developing a bespoke roadmap, and will offer more sustainable products that meet today's consumer expectations, all without compromising your performance.

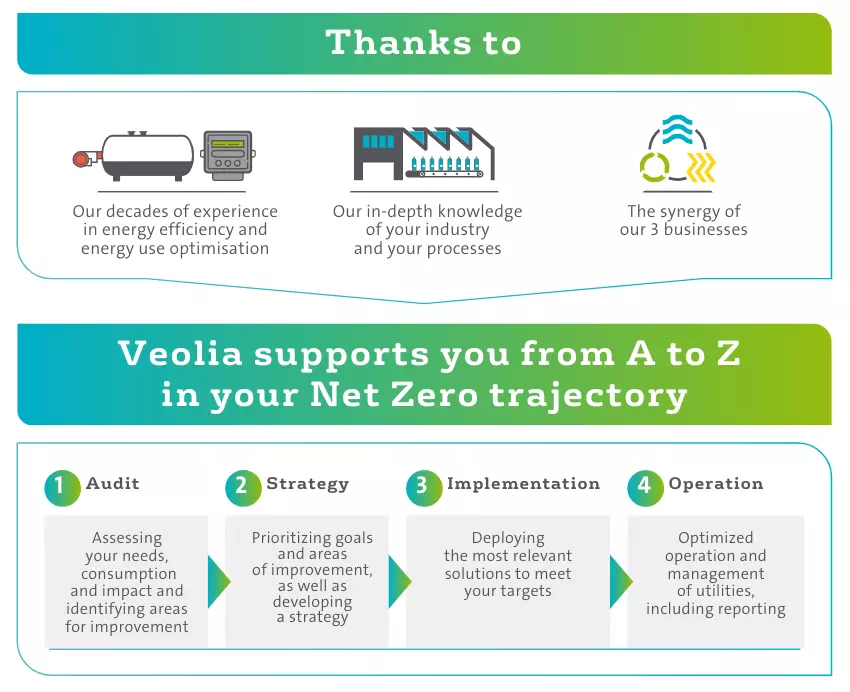

Connect with a network of experts

Receive comprehensive support in your decarbonization

journey from a leading player in energy management.

Benefit from the expertise of our experts, distributed around

the world, who possess technical knowledge of the Food and

Beverage industry and a deep understanding of local

challenges. With their collaboration, you can audit your

facilities, establish a decarbonization strategy for the short or

long term, and implement tailored solutions.

María José is Energy Efficiency Manager at Veolia

"Securing energy supply will turn the tide!"

Improve the energy efficiency of your assets

Your industrial installations consume a significant amount of energy in the form of heat, cold and compressed air. Energy efficiency is a key aspect of decarbonization. By entrusting us with the management of your systems, you can ensure the harmonization of operational and environmental performance.

Massively producing steam while reducing energy consumption.

On the site of The Kraft Heinz Company in Kitt Green, the largest food-canning plant in Europe, Veolia has deployed a facility capable of generating up to 140 tonnes of steam per hour. This installation reduces CO2 emissions by 8% and lowers the annual energy bill by £500,000.

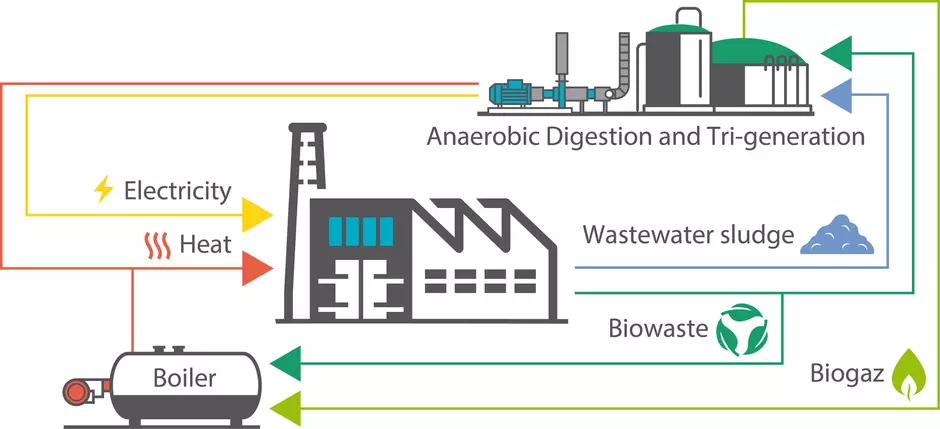

Produce energy on-site

Reducing your reliance on fossil fuels and shielding yourself from the fluctuations of energy prices is possible through on-site energy production (with locally sourced low-carbon fuels). With Veolia's expertise and innovation capabilities, customized solutions can be developed to transform your outgoing flows (organic waste, wastewater, etc.) into resources for electricity or heat production.

Contribute to the carbon-neutrality of the factory, thanks to biogas production from wastewater

Within the new fresh milk processing plant of Arla Foods in Aylesbury, Veolia has implemented its Memthane® solution, capable of treating 800m3 of wastewater per day to generate biogas, hence contributing to make the plant carbon-neutral.

They are already decarbonizing their Food and Beverage value-chain

Transforming used bottles into new water bottles

In partnership with Sources ALMA, a major European producer of mineral water, Veolia has established the FILAO recycling plant, where 40,000 tons of used bottles are annually transformed into high-quality plastic granules before being used to produce new water bottles.

Reducing the Carbon Footprint of a Meat Substitute Factory

Within a Quorn meat substitute production facility, Veolia has implemented a cogeneration plant, enabling on-site production of electricity and heat, thereby reducing the energy consumption and

carbon emissions of the site.

Recycling the biogas produced from organic waste to generate heat

To produce industrial steam at a lower cost in the Bonduelle canned vegetable factory in Nagykőrös, Veolia has implemented a solution capable of generating 350,000 m3 of biogas annually from the organic matter present in the factory's wastewater.

Management and monitoring of utilities for a large packaging site

Veolia oversees the management and maintenance of the supply of steam, compressed air, refrigeration, nitrogen, carbon dioxide, and filtered process water for Diageo's beverage packaging site. All while ensuring a reduction in the site's energy bill and environmental footprint.

Treating wastewater efficiently and producing green energy

Veolia partnered with Hershey to develop an advanced and highly effective wastewater treatment process to meet the current and future needs of the manufacturer. This facility also enables the production of 6.5 GWh of biogas per year.

Closing the loop from plastic waste to new bottles

The Veolia TorrePET plant processes 60,000 tons of plastic waste each year and transforms them into 34,000 tons of Plastiloop high-quality food-grade rPET pellets, enabling the production of 1.4 billion new plastic bottles.

The ecological transformation is within reach, don't wait any longer!

No matter your position in the proverbial farm-to-fork value chain, Veolia solutions can be deployed to help you reduce your greenhouse gas emissions. Feel free to contact our experts to conduct an audit of your facilities and your inputs and to establish a decarbonization roadmap.